Error de formato de correo electrónico

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

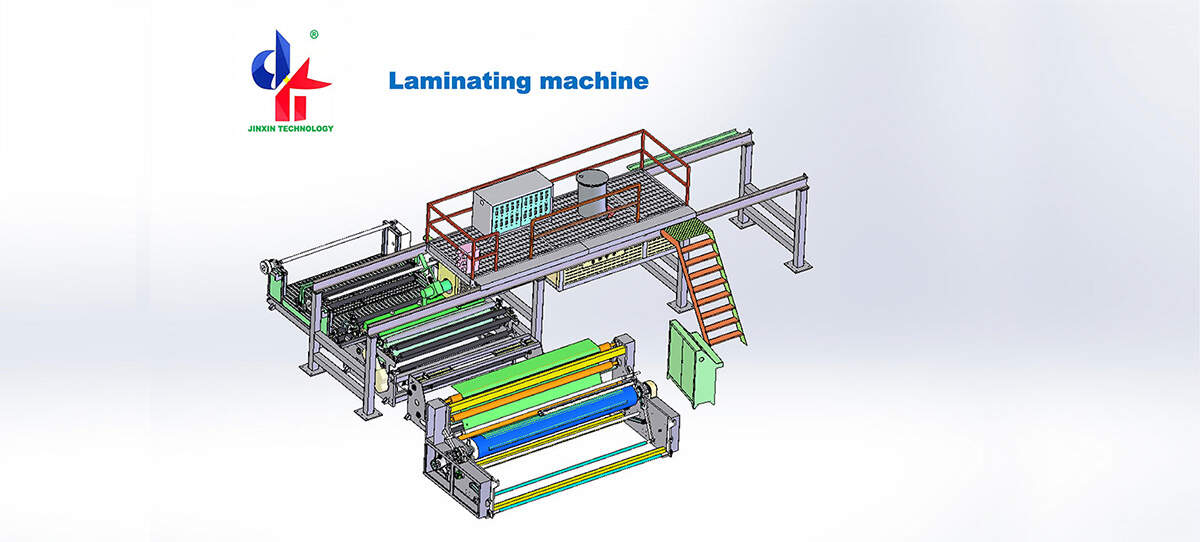

Auto Nonwoven Fabric Laminating Machine with Glue Machine for Film Laminating Coating Cheap Price Flute Laminating Machine Paper

Energy economy, rapid output, and high precision are definitely necessary qualities for a successful nonwoven lamination machine. The dedicated quality and tension controls, two essential components when it comes to the lamination of delicate material to assure the excellent quality of the finished product, are what really set the best machine apart. It's also crucial to keep in mind that the nonwoven lamination machine is a component of a bigger system that also includes machines used for other purposes, and that it must cooperate with these other machines to make sure that the entire system's operation, from start to finish, runs smoothly.

| Model | JX-laminating machine | ||

|---|---|---|---|

| Product Width | 1600mm | 2400mm | 3200mm |

| Equipment Size | 12*10*3.5m | 12*12*3.5m | 12*16*4.5m |

| Mechanical Speed | 200m/min | 200m/min | 150m/min |

| Thickness | 0.01~0.1 mm | 0.01~0.1 mm | 0.01~0.1 mm |

| Daily Output | 2-3T/Day | 3-4.5T/Day | 4-5.5T/Day |

| Transformer Capacity | ≈80KVA | ≈120KVA | ≈180KVA |

| Power Consumption | 520°-650°Ton | 520°-650°Ton | 520°-650°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

The Best Nonwovens Lamination machine

The characteristics that a good machine for nonwoven lamination must have are undoubtedly energy efficiency, high production speed, and great precision.

However, what truly sets the best machine apart is the dedicated quality and tension controls, two critical elements when it comes to the lamination of fragile material to ensure the high quality of the final product.

It is also important to remember that the nonwoven lamination machine is part of a larger system that includes machines dedicated to other tasks and that it must work in sync with these other machines to ensure that the entire process from the beginning to the end of the system flows smoothly.

This means that when the nonwoven materials are laminated, the final composite must transition to the next machine, whether that is packaging, material handling, or converting lines, without losing the properties or characteristics of the original materials.

In addition, the machine should provide

Short changeover time

Heavy-duty construction

Several control zones and fast setup capabilities

Winders and unwinders that include double stations in order to change rolls while the machine is operating

A centralized control panel with data collection and business intelligence capabilities

A pneumatic edge guiding system for unwinding and/or rewinding

The JINXIN complete turnkey line provides high-quality adhesive, thermal, and ultrasonic lamination, as well as unwind stands, laminating stations, and in-line slitting winders. Moreover, among the optional components you can request you can find:

web accumulation system

trim & dust suction system

DMS (Defect Management System)

in-line printing unit

master roll and finished reel handling system

Contact us for more information about our Lamination Solution or to request a free consultation.

FAQ

Q1: How do you ship the goods and how long does it take to arrive?

A1: We usually ship goods by LCL or FCL by sea, by air, or express delivery. Usually, it takes 30 days by sea, 5-7 days by air, or express delivery.

Q2: How about the after-sales service and warranty?

A2: The warranty period is one year and after-sales service is lifelong.

Q3: How does your factory do regarding quality control?

A3: Quality is a priority. We always attach great importance to quality control from raw material to the very end product. Our factory has gained CE and ISO 9001 authentication.